For us at Flymax, the coffee break is a moment to be cherished.

It is a moment when we disconnect from work and colleagues become friends, because it is during these 10 minutes that we really get to know the people we spend most of our day with.

When enjoyed in public spaces, the 'coffee break' becomes a moment of relaxation that people, alone or in groups, decide to treat themselves to.

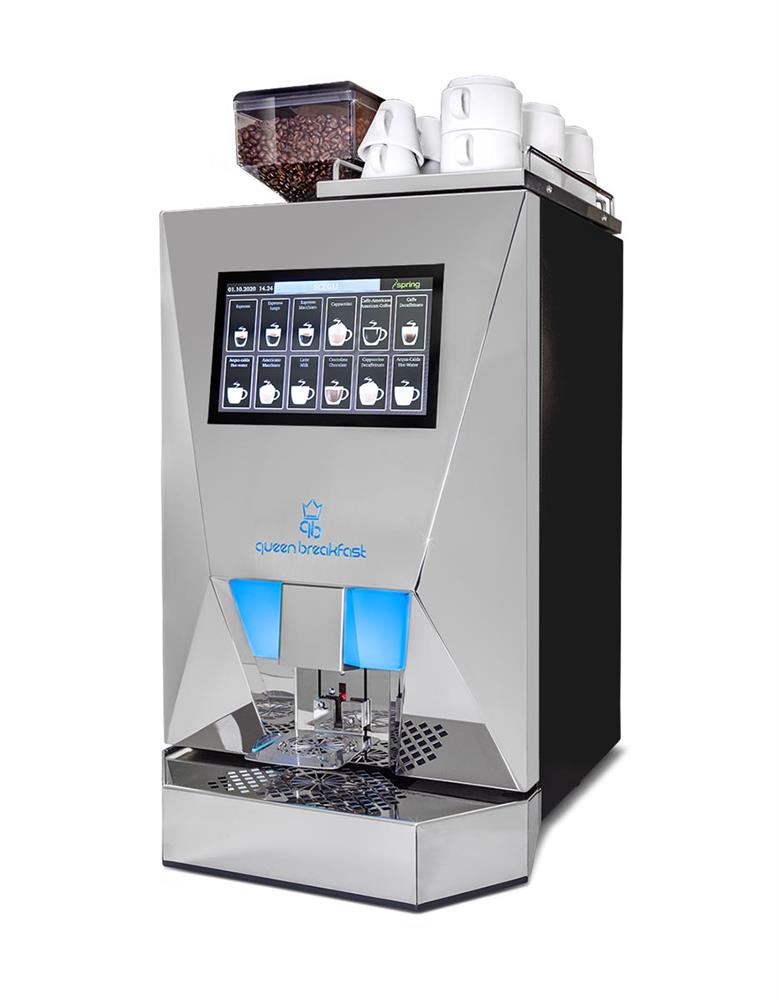

For these reasons, coffee must be good and easy to enjoy.

This is the main reason that drives us to continuously improve the technology and functionality of our vending machines.

Below, we will illustrate three of our main innovations that improve the coffee break.

Fresh milk and quality of the final drink

One of the most popular drinks consumed during breaks is undoubtedly coffee and caffè macchiato, so why settle for less?

It was back in 2015 when, during a coffee break, one of us thought, "It would be nice to have a macchiato like at the bar, with fresh milk instead of powdered milk..." and from there we began to think about how we could develop this project, which became a reality when, a few months later, a new customer asked us for a model that used fresh milk.

Initially, the fresh milk circuit included an exchanger through which the milk passed directly, was heated and then poured into the cup.

After several years, we decided to implement this system to improve both the maintenance and durability of the circuit.

Therefore, we introduced our new system with a heat exchanger for fresh milk and a milk suction and mixing pump, which replaced the exchanger to generate steam and the cappuccino maker.

The frothed milk is therefore generated by air and no longer by steam.

In order to maintain proper hygiene in the milk circuit, two different washing cycles have been set up:

● Short (automatic): 5 minutes after the last dispensing of fresh milk, the machine will automatically empty the milk circuit and fill it with water.

● Complete wash (manual at the end of use): the machine will guide you step by step and you will need a specific detergent to wash the circuit. For good hygiene and maintenance, it is advisable to perform this wash daily, at the end of the machine's period of use.

The difference in quality between a macchiato and/or cappuccino made with fresh milk and/or powdered milk is easily noticeable.

Not only is the flavour different, but the consistency of the foam is also different.

The natural sugars in milk, rather than the chemical sugars in powder, leave more room for the taste of coffee.

For this very reason, in recent years, the demand for models with fresh milk has grown significantly, not only in Italy but also among our overseas customers, who have presented us with an additional challenge: adapting the machines to the quantity of beverage dispensed by them, which is certainly not the same as in Italy.

In a world that is increasingly focused on the quality of ingredients rather than quantity, the choice between 'fresh' and industrial is obvious.

Telemetry and remote control

At Flymax, we began to approach the world of telemetry and remote management in 2016, with a first draft of a programme that was fully customisable by the customer.

At that time, telemetry was not yet such a pressing need for our customers, but for about three years now, everyone has wanted it.

Time has remained the same, but the number of things to do has doubled, as have the number of trips and areas of intervention. Therefore, customers need a tool that can remotely control their distributors, not only on a daily basis, but also statistically (how much product the machine has used, in what time, how many errors it has had, etc.).

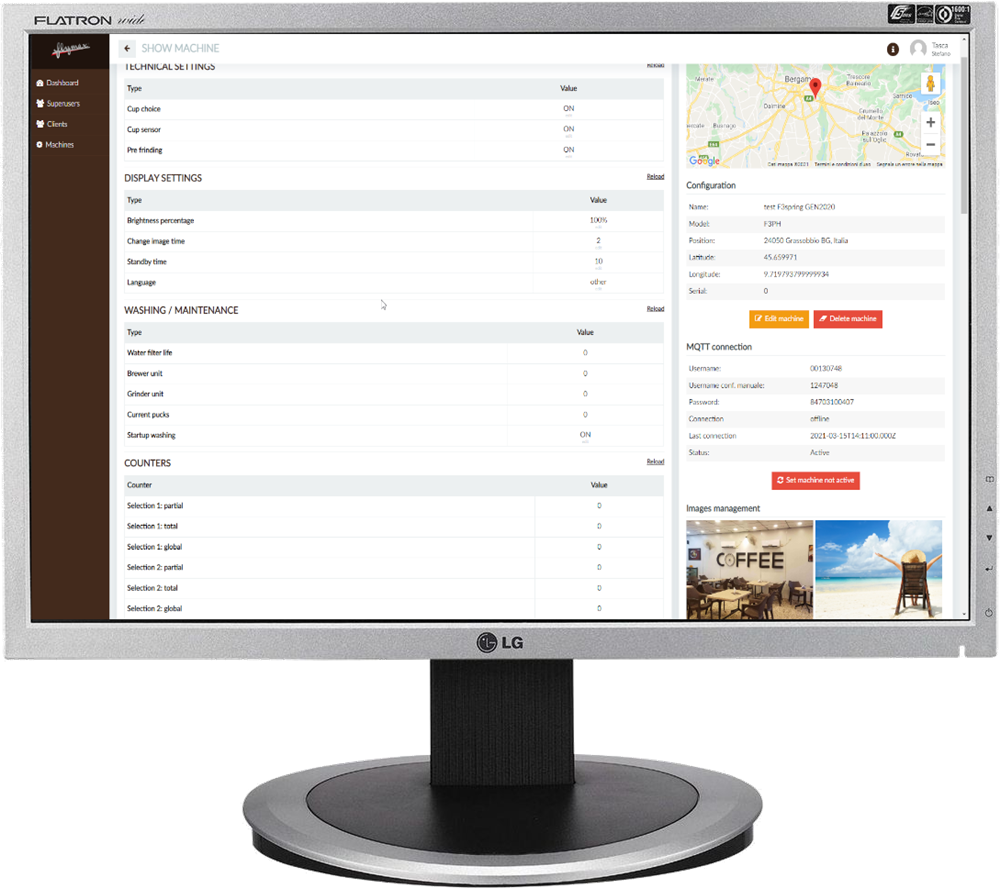

Our telemetry system is designed to be customised by the customer to meet their every need.

From the development of a simple and intuitive dashboard to the most advanced remote control functions such as: dispenser status control, product quantities, dose adjustments and much more.

Geolocation also allows you to know where the distributors are located and their level of performance in order to have a clear and accurate commercial and technical report.

This technology reduces the costs of preventive maintenance, as the data collected can be used to predict approximately how often the main parts (unit, boiler) need to be replaced based on their usage.

Please note that both routine and extraordinary maintenance is always mandatory on site, in front of the dispenser. We do not recommend maintenance and/or dosage changes with machines operating remotely, as it is not possible to predict how the machine will behave in the absence of qualified personnel.

Cashless payments and digitalisation

Another technological innovation that has gained considerable momentum since the pandemic is undoubtedly digital payment systems, i.e. credit cards, apps and all those transactions that do not require cash payments.

Most of our vending machines are set up for MDB and Executive protocol systems, and since customers mostly use their own payment systems, we have always tried to adapt the configuration of our vending machines so that the aesthetic impact is not affected.

For several years now, we have been successfully testing the Self Blue payment system, which allows customers to pay for their drinks directly via their smartphones using an app.

The system uses a Bluetooth connection and, through the application, it is easy to choose the dispenser, purchase a drink and top up your credit.

No more coins, tokens and keys in your pockets, just one tap to get your drink!

All of the technologies described above are undoubtedly aimed at improving coffee breaks in terms of quality, efficiency and versatility.

If you are looking for a company that can enhance your customers' coffee break, please contact us!